Understanding Challenges and Solutions

Metal Retrofit System Installation Process

Metal roofs have their own unique problems due to their constant movement from expansion and contraction. That movement places a lot of stress on all of the components of the system. The below slide show series shows the step-by-step procedure of our Metal Retrofit System

Panel end laps

Panel end laps are also stressed by the panel movement. At the time of installation sealants are typically used where the panels overlap. Eventually those sealants become old, dried and deteriorated and the movement of the panels causes the deteriorated sealants to dislodge. After the sealants are gone and the end-lap fasteners are loose panels separate somewhat and allow moisture to enter the lap then into the building.

Rust

Planned Maintenance of a metal roof system is critical to keep it properly fastened to the structure and watertight. Missing and loose fasteners need to be replaced with new and oversize fasteners to keep the metal components tight to each other. Coatings are often used to address rusted fasteners, panel end laps and other areas where the movement of the metal has created openings. However, coatings are not the end-all answer. Coatings are a maintenance item and must continuously be reworked throughout the life of the metal roof. Caution needs to be exercised as there are many different types of coatings and coating repair systems and some of them are actually deleterious to metal roofing panels.

Roof coatings

Eventually metal roof systems reach the point that they can no longer prevent water migration or they are no longer stable for the overall structure. Sometimes the decision is made to coat the entire roof system and the same cautions are expressed. Coating may buy a little more time but it is still a maintenance item that must be addressed every 3 to 5 years. An additional concern is that a full coating may hide some problems that are dangerous to roof top traffic

Revitalize Your Metal Roof with CIRSCO's Innovative Retrofit Solution

Metal Roof Retrofit System by CIRSCO

A third option is a Metal Roof Retrofit system by CIRSCO. This system allows the existing metal roof to remain in place and a new white, heat reflective, energy-saving, insulated monolithic covering over the entire area and carries a 15-year manufacturer’s warranty for labor and materials.

Fastener and Component Inspection

The first step is to address all fastener and loose component items as is necessary. New wood blocking is fastened to the structure to allow perimeter fastening of the new membrane system as well as new gutters.

Enhancing Substrate Uniformity

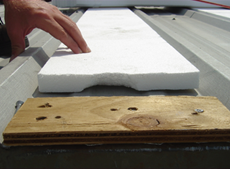

Next the areas between the rib sections of the metal roof system are in-filled with new insulation to create an even substrate at the height of the rib sections

Installation of New Recover Board

Then a new recover board is installed over the entire roof area. The board serves as an underlayment for the new membrane and provides a smooth monolithic surface.

Installation of White Membrane Roof System

Then the new white membrane roof system is installed over the recover board and is fastened to the structure in accordance with Factory Mutual and prevailing building code uplift requirements.

Installation of Metal Trim, Gutters, and Downspouts

Finally new metal trim and/or gutters & downspouts are installed.

Comprehensive Warranty Coverage

The completed system is warranted by the manufacturer of the membrane for labor and material for extended periods of time in accordance with the specification used.